DIY Vantec modification

Introduction

This page describes a particular behaviour of certain Vantec

speed controllers and one way to change that behaviour. Note that no guarantee

is given for this procedure. You should not attempt to modify any speed

controller unless you are thoroughly competent with soldering small electronic components. If

you have to return your Vantec to the manufacturer, and this modification is

present, you will probably be charged for rectification work. This modification

has been performed on several Vantecs (more than one model) and so far has

worked fine, but it is not condoned by Vantec and there is no guarantee that it will work on yours, or will not

change some other property of the controller. You're on your own!

If you are not experiencing the behaviour described below, it is recommended

that you do not make any changes to your controller. If it isn't broken...

Description

It has been noticed by several people that when certain Vantecs (it has been

observed on several different models of Vantecs) are used in certain situations,

there is the possibility of the Vantec resetting itself under high-load

conditions. Alan Gribble, creator of the great Pussycat, observed this behaviour

on one of his Vantecs a couple of years ago and set about finding a 'fix'. After

some considerable research, he developed the procedure described below. Many

thanks to Alan for allowing the procedure to be publicised.

We observed it when running our RDFR47E at 36 Volts (three sets of 3Ah

NiCads) driving a pair of Bosch GPA 750 motors. In retrospect, it was also what

caused KHz mobility problems in BattleBots Season 4 against Little Sister and

Surgeon General. Whenever a full power start was

attempted, the Vantec would reset, which would cause the motors to loose all

power for about one second. After the one second, the controller would recover

fully.

If driven around 'softly', there would be no problem. The behaviour was

also noticed when running at 24 Volts, but less so. Once the 24V batteries had

been discharged to around half capacity, the controller usually behaved fine, so

it seems to be related to the amount of load that the controller is having to

handle - light loads and everything is OK (you will not be able to reproduce it

with the machines wheels in the air), but over a certain limit, the behaviour

starts appearing.

We attempted other solutions, like fitting a large capacitor to the input

lines on the Vantec and several ferrite sleeves to the motor leads, but with no noticeable

effect.

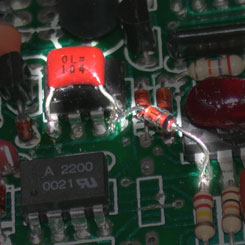

There

was thought to be a factory 'fix' for this behaviour. On Vantecs purchased since

the middle of 2001, maybe earlier, it has been noticed that a capacitor and

diode had been added to the circuit board, highlighted on the picture on the

left. Click on the picture for a larger view. However although our Vantec RDFR47E, purchased in late 2001, had this

'fix', it still exhibited the behaviour.

There

was thought to be a factory 'fix' for this behaviour. On Vantecs purchased since

the middle of 2001, maybe earlier, it has been noticed that a capacitor and

diode had been added to the circuit board, highlighted on the picture on the

left. Click on the picture for a larger view. However although our Vantec RDFR47E, purchased in late 2001, had this

'fix', it still exhibited the behaviour.

Altering the behaviour

The procedure involves soldering two new components

onto the control board of the Vantec. The controller should not need to be disassembled.

The components are:

60 Volt, 5 µF electrolytic capacitor e.g. RS

partno 324-5335

10 K Ohm resistor

It is also recommended that you attach an AC Varistor/Transient Voltage

Suppressor across each of your motors. e.g. RS partno 354-5180, manufacturers

partno P6KE47CA. This

cuts down on voltage spikes generated by the motors getting into the controller.

The positive end of the cap and one end of the

resistor are both soldered onto pin one of the 14 pin DIL chip on the right of

the picture. The negative end of the cap is soldered into an unused solder pad on

the board and the other end of the resistor is soldered onto a nearby

track.

The positive end of the cap and one end of the

resistor are both soldered onto pin one of the 14 pin DIL chip on the right of

the picture. The negative end of the cap is soldered into an unused solder pad on

the board and the other end of the resistor is soldered onto a nearby

track.

To

solder the resistor to the track, take a sharp knife and carefully scrape off

the green varnish, exposing a few mm of bare track. The exposed track, and the

solder pad for the cap are circled in the picture. Be very careful not to

damage the track itself. You may need to use a magnifying glass - those tracks

are small!

To

solder the resistor to the track, take a sharp knife and carefully scrape off

the green varnish, exposing a few mm of bare track. The exposed track, and the

solder pad for the cap are circled in the picture. Be very careful not to

damage the track itself. You may need to use a magnifying glass - those tracks

are small!

You can now solder the resistor in place. One

end is soldered onto pin one of the chip, although in this case, the controller

had the factory 'fix', so it was easier to solder onto the leg on the diode that

is also attached to pin one.

You can now solder the resistor in place. One

end is soldered onto pin one of the chip, although in this case, the controller

had the factory 'fix', so it was easier to solder onto the leg on the diode that

is also attached to pin one.

The capacitor can now be soldered in place.

The negative wire should be passed through the solder pad hole. Be careful to

crop the wire before soldering so that it does not protrude too far from the

other side of the board. It may not go all the way through the hole - ours was

blocked by glue on the other side. The positive wire is also attached to pin one of the

chip.

The capacitor can now be soldered in place.

The negative wire should be passed through the solder pad hole. Be careful to

crop the wire before soldering so that it does not protrude too far from the

other side of the board. It may not go all the way through the hole - ours was

blocked by glue on the other side. The positive wire is also attached to pin one of the

chip.

Once you are happy all is secure, put a

blob of contact adhesive or cyano on the components to keep them in place. Done!

That's all you have to do. Go and test it and keep your fingers crossed.

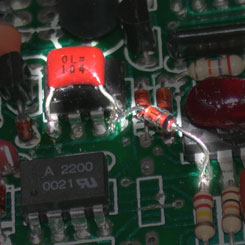

There

was thought to be a factory 'fix' for this behaviour. On Vantecs purchased since

the middle of 2001, maybe earlier, it has been noticed that a capacitor and

diode had been added to the circuit board, highlighted on the picture on the

left. Click on the picture for a larger view. However although our Vantec RDFR47E, purchased in late 2001, had this

'fix', it still exhibited the behaviour.

There

was thought to be a factory 'fix' for this behaviour. On Vantecs purchased since

the middle of 2001, maybe earlier, it has been noticed that a capacitor and

diode had been added to the circuit board, highlighted on the picture on the

left. Click on the picture for a larger view. However although our Vantec RDFR47E, purchased in late 2001, had this

'fix', it still exhibited the behaviour.